Plant Engineering – Pipeline Construction

Satisfied customers are our best recommendation! Here you will find a selection of our projects, which reflect the comprehensive range of services of MF Engineering.

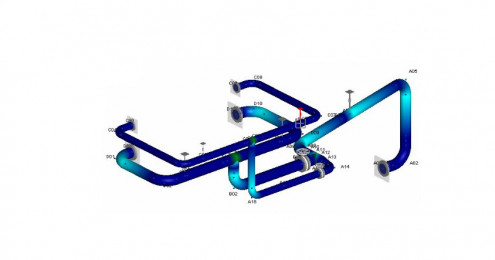

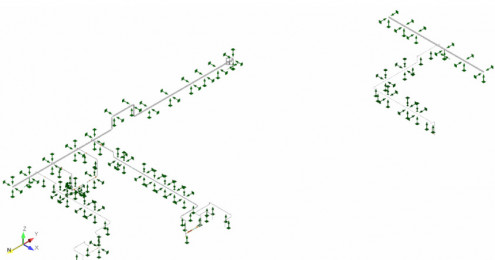

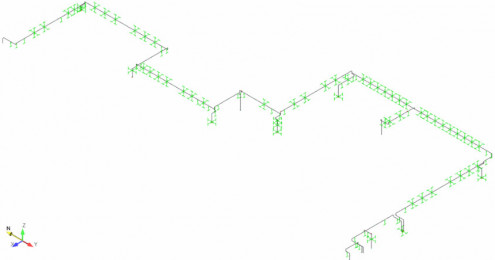

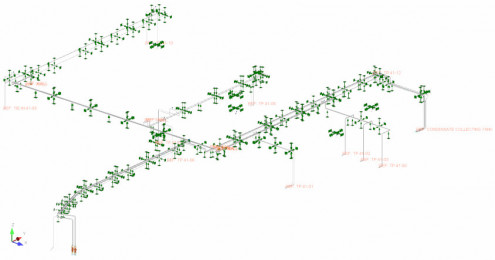

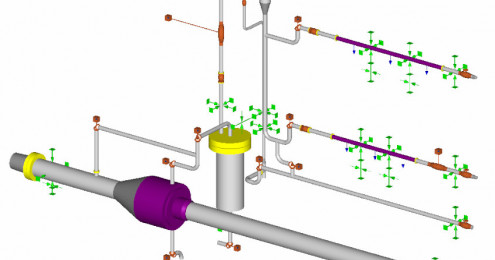

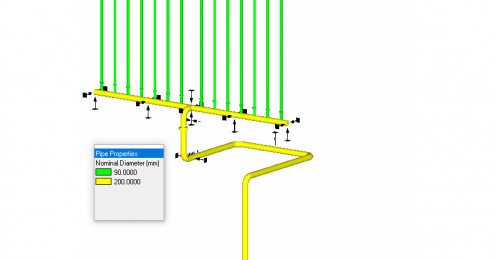

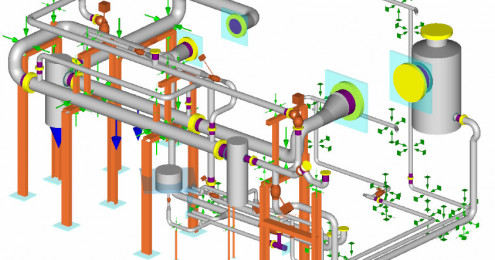

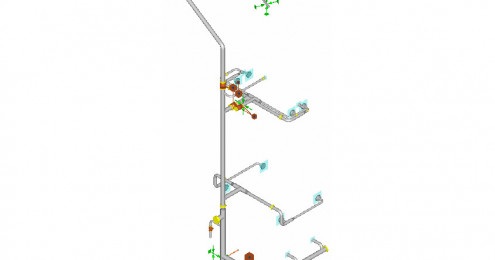

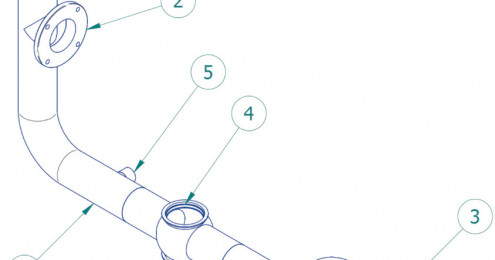

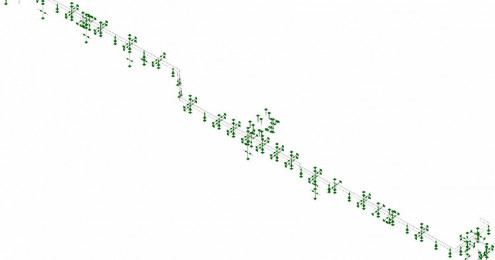

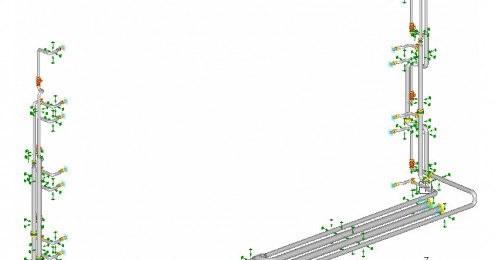

Calculation of a steam and a condensate pipe line (operating temperature of 180°C, pressure 10 bar)

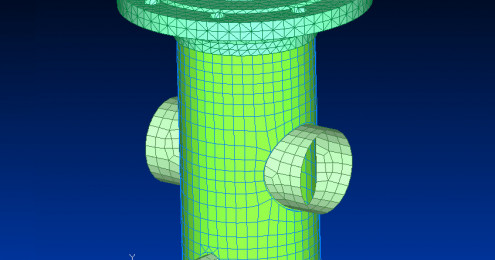

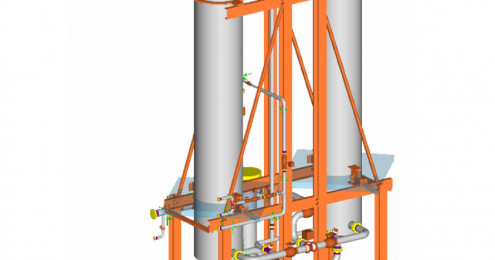

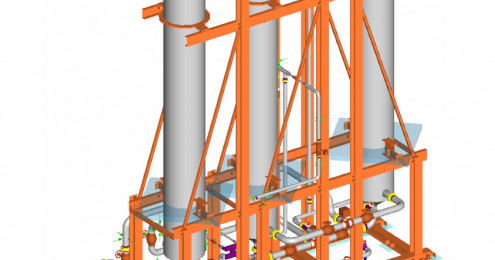

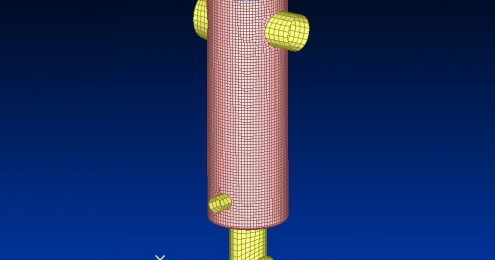

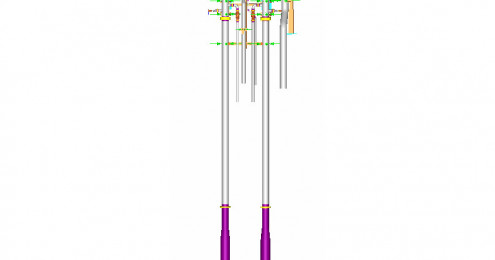

New development and erection of dryer DN800 and purifier DN700 in Golden, Colorado, USA